Ultraviolet (UVC or UVGI) air purification technology requires the right application to be effective. The way Air Sniper utilizes powerful bulbs and reflective paneling to control the intensity, dwell time, CFM, and irradiation proximity within the equipment creates the ultimate pathogen destruction environment. Together, these elements form an environment within the Air Sniper unit that is rich with Ultraviolet Germicidal Irradiation (UVGI).

When using UVGI for air purification, it is crucial to measure the effectiveness of the system from a holistic perspective. Four elements, namely intensity, proximity, dwell time, and CFM, ensure UVGI technology optimization is achieved.

Intensity is a key driver in the effectiveness of UVGI air purification, as pathogens and harmful bacteria may circulate back into the environment if the UVC intensity is not sufficient. Air Sniper uses several methods to combat this loss, such as increasing the number of bulbs, the wattage of each bulb, ensuring that the air is in close proximity to the UVC bulbs, and the reflective material throughout the unit.

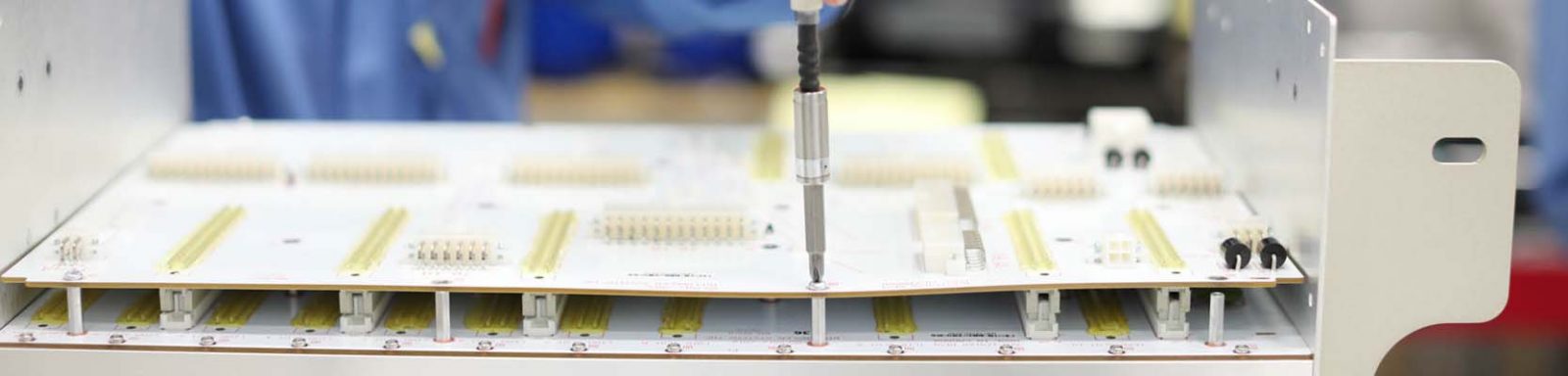

Proximity to pathogens and contaminants is crucial for its ability to function as a germicidal solution. Therefore, in designing air purification solutions like the Air Snipers, it is essential to have multiple bulbs throughout the unit’s interior. This accomplishes the dual goal of providing proper UVC intensity and ensuring the space between bulbs is not large enough for the light to lose its required intensity.

As a measure of airflow, cubic feet per minute (CFM) plays an important role in determining the effectiveness of air purification equipment. It is part of the calculations necessary to determine dwell time, and the fans must be powerful enough to circulate all the air within a space in a reasonable amount of time.

UVGI has been proven for germicidal use, making it a common use for air purification. Specifically, UVGI light at a spectrum of 253.7 nanometers is used for germicidal use, since other wavelengths are prone to producing ozone. By using multiple bulbs in conjunction with a reflective environment, Air Sniper equipment can revolutionize the way we look at cleaning our air.

Using reflective materials in UVGI purification units allows the UVC light waves to retain their effectiveness. An environment with sufficient reflective capabilities can maintain the UVGI light necessary to reduce pathogens and remove harmful contaminants from the air. Finally, proper product design is necessary to ensure the equipment does not create shadowing within the unit where the light cannot penetrate.

Photocatalytic Oxidation (PCO) technology was originally developed by NASA. While there may be several methods of creating a PCO element, Air Sniper forces the air through the holes of a stainless-steel weave coated in anatase titanium dioxide to generate that reaction, maximizing the proven effectiveness of the PCO elements in accompaniment to the already-powerful purification effects of UVGI.

Explore cutting-edge supplemental air purification techniques in the whitepaper ‘Using UV-C to Improve Indoor Air Quality and Save Money.’ Learn how UV-C technology, particularly UVGI, reduces airborne infections and enhances HVAC efficiency. Download for key insights into transforming your indoor air quality.

Call or email us, or fill out the form to have one of our customer service specialists get in touch with you.

EPA Facility Registration Number 100516-CAN-1

Bay 11, 6565 – 40th St SE. Calgary, AB T2C 2J9, CA

Phone: +1.888.338.9549

Email: [email protected]

Copyright 2024 AIR, Alpine Innovative Research Inc.

Website & marketing by our

marketing agency in calgary.